Current Research Activities

Current Research Activities

- Generation of polymer composites for drug delivery

- Development of interpenetrating polymer networks for use as implants

- Synthesis of compounds in Dense Gas media

- Sterilization using Dense Gas

- Particle engineering to improve bioavailability of pharmaceutical compounds and to allow different administration routes

- Extraction and purification of natural product for therapeutic application

- Microfluidics

Particle Engineering Techniques

- Rapid Expansion of Supercritical Solutions (RESS)

Material is dissolved in a dense gas and sprayed into a low pressure chamber. Precipitation occurs due to the high reduction in density and solvation power of supercritical fluid (SCF) as it transits to the vapour phase. - Particles from Gas Saturated Solutions (PGSS)

Dense gas is dissolved in a solid material which melts. Precipitation is induced by spraying the gas saturated solution via a nozzle into a low pressure chamber. Depressurization results in a temperature quench whereby the previously melted phase solidifies. - Gas Antisolvent Precipitation (GAS)

A batch precipitation technique that uses near critical or supercritical fluid anti-solvents to precipitate solutes from solution. The GAS process was originally developed by Gallagher et al. (1989) and has since been shown to have application in the crystallisation of drugs, polymeric microspheres explosives, and the purification of organic acids. Operating pressures of GAS processing are comparatively lower than other processes and supercritical conditions are not required. This dense gas precipitation technique injects miscible anti-solvent in a liquid phase solution to cause the volumetric expansion and therefore decrease in solvent power of that phase. As the anti-solvent has no affinity for the solute, the solvent power of the solvent is a unique function of its density, or the intermolecular distances between the solvent molecules. Therefore at a critical anti-solvent concentration or expanded volume the solution becomes saturated. At higher anti-solvent concentrations precipitation of the solute results. After the precipitation phase the product is filtered and washed at the same pressure, whilst the solvent is in expanded state, to prevent re-dissolution into the solvent. Therefore the nature of the final precipitate which is determined by the volumetric expansion rate is a function of the pressurisation rate, temperature and the type of solvent and anti-solvent used. This research has been motivated by the need to refine the mode of delivery and therefore the effectiveness of therapeutic compounds. Many modern drug administration techniques make use of controlled release systems that are able to more closely model the natural release of a drug. Controlled release processes may simply involve drug modifications to delay or enhance chemical diffusion through membranes or even the encapsulation of the active component in a microporous or bioerodible solid such as polymer. It has been accepted that no method of drug delivery can duplicate the control and response of the human body, but it is hoped that the production of uniformly sized particles can signification improve the control of drug absorption rate. Such well defined powdered compounds may have application in encapsulated medicines or in the aerosol delivery of drugs to the lungs. In both cases particles in the 1 to 5 mm range are ideal. At this size powders are small enough to get lodged in the alveoli, within the respiratory system, but large enough not to be exhaled. - Aerosol Solvent Extraction System (ASES)

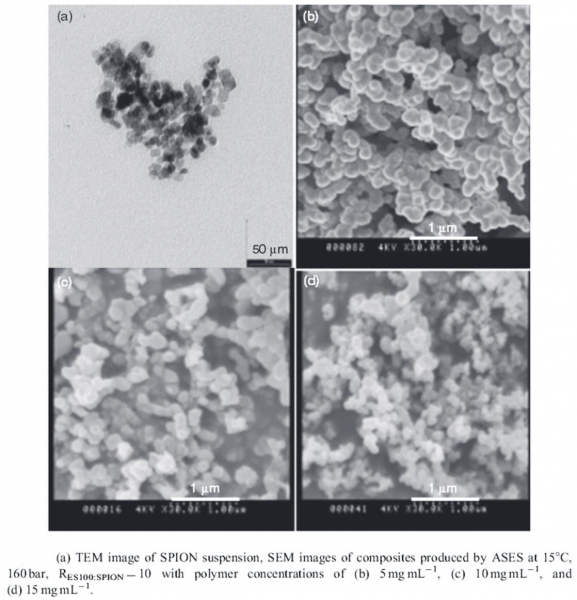

Material is dissolved in an organic solution and sprayed into a chamber containing a high pressure dense gas, causing particles to precipitate. The example below was using an ASES process to coat the superparamagnetic iron oxide nanoparticles (SPIONs) with a pH-responsive polymer - Eudragit R S100 (ES100). [1]

[1] - Atomized Rapid Injection for Solvent Extraction (ARISE)

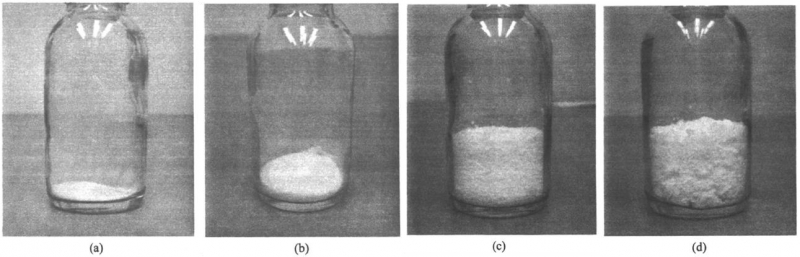

Similar to the GAS and the ASES processes, the ARISE process uses the antisolvent abilities of a dense gas such as CO2 to effect the precipitation of solutes from their dissolved forms. The ARISE process eliminates the use of capillary nozzles for solution atomization and is able to effect precipitation over a much larger volume. ARISE200mg bovine insulin in 50ml sample bottles (a) lyophilized; (b) ARISE process operated at 90 bar; (c) ARISE process operated at 120 bar; (d) ARISE process operated at 150 bar [2]

ARISE200mg bovine insulin in 50ml sample bottles (a) lyophilized; (b) ARISE process operated at 90 bar; (c) ARISE process operated at 120 bar; (d) ARISE process operated at 150 bar [2] - Depressurization of an Expanded Solution into Aqueous Media (DESAM)

It is a process to generate nano-carrier systems such as liposomes, polymersomes and micelles. The raw materials to generate nano-carrier systems are solubilised in a suitable organic solvent and pre-expanded to a threshold pressure that is below the pressure where the raw materials precipitate. The expanded organic solution is then delivered into a bottom vessel which contains an aqueous media via a nozzle by the pressure gradient. Nano-carrier systems form by self-assembly when the organic solution comes in contact with the aqueous media.[3,4]

- Supercritical Fluid Extraction (SFE)

Supercritical fluid extraction is an attractive technique for selectively extracting compounds from plant matrices. Extraction using supercritical CO2 has several advantages over hydro-distillation, steam distillation and solvent extraction including operation at lower temperatures thus preservation of the thermally labile components in the extracts and elimination of the problem of toxic residual solvent in the products. Furthermore, SFE retains the organoleptic characteristics of the starting plant materials, which may not be preserved by the traditional extraction methods. Particularly, the high selectivity of the extraction process and the reduced potential for oxidation of the extracted materials make this technique especially suitable for extractive isolation of naturally therapeutic compounds.

Reference

[1] U.T. Lam, R. Yoganathan, A.G. Carr, R. Mammucari, N.R. Foster, Encapsulation of Superparamagnetic Iron Oxide Nanoparticles by the Supercritical Antisolvent Process, Australian Journal of Chemistry, 65 (2012) 40-44.

[2] N.R. Foster, R. Sih, Development of a Novel Precipitation Technique for the Production of Highly Respirable Powders: The Atomized Rapid Injection for Solvent Extraction Process, in: Gas-Expanded Liquids and Near-Critical Media, American Chemical Society, 2009, pp. 309-347.

[3] C.C. Beh, R. Mammucari, N.R. Foster, Formation of nano-carriers by the depressurization of expanded solution into an aqueous media (DESAM) in: Chemeca 2011: Engineering a Better World, Barton, A.C.T.: Engineers Australia, Sydney Hilton Hotel, NSW, Australia, 18-21 September 2011, 2011, pp. 166-174.

[4] C.C. Beh, Formation of nano-carrier systems by dense gas processing, in: School of Chemical Engineering, UNSW Australia, Sydney, Australia, 2013, pp. 225.